Many manufacturers struggle with balancing accuracy, cycle time, and Gage R at the leak test station-particularly when faced with a leak test with complex requirements like large volume leak test, variable volume, multi-cavity parts, etc.

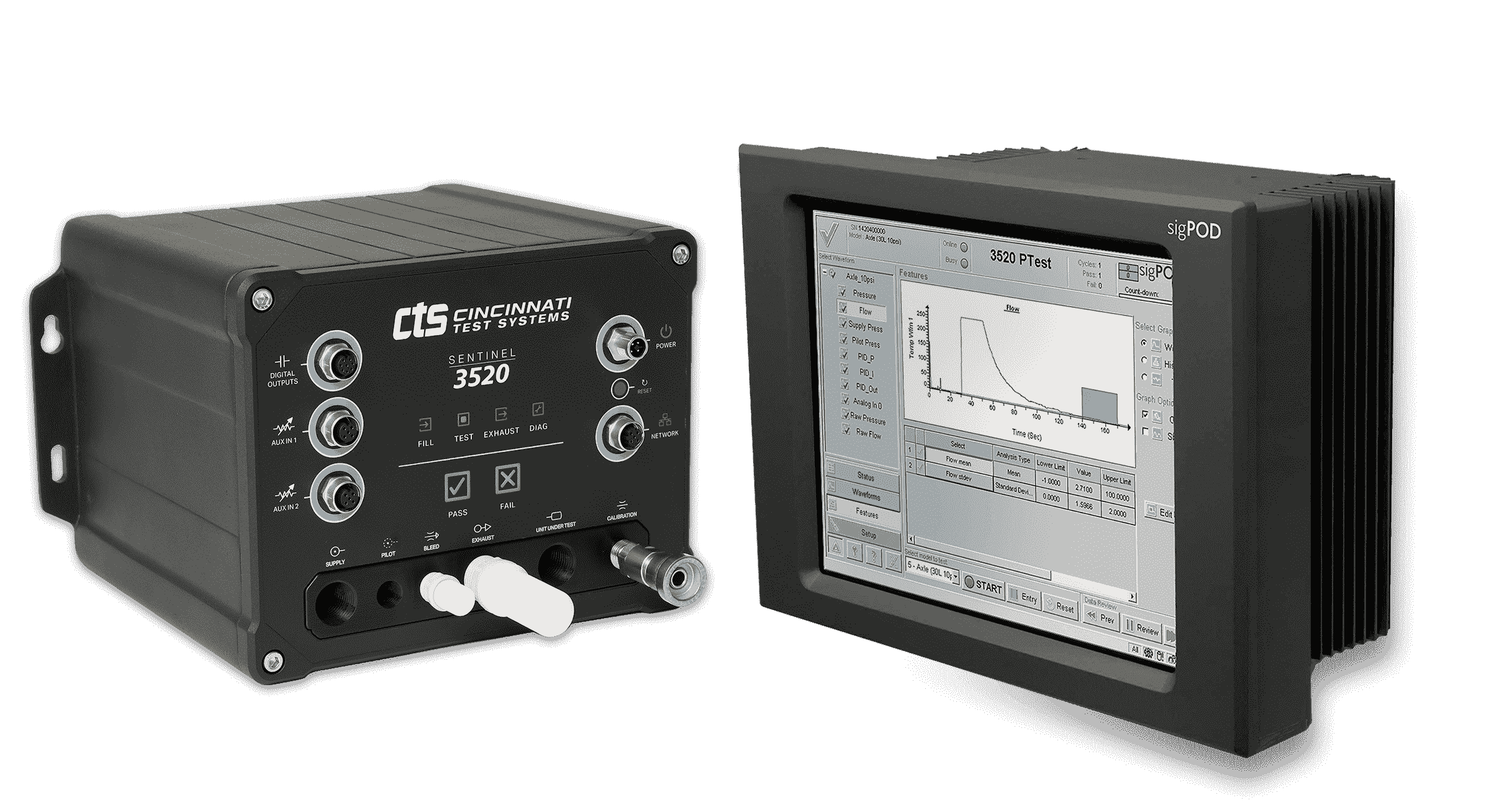

These test scenarios require a precise balance of pressure control, flow range and fill rate to get an accurate reading and meet cycle time requirements, which the Sentinel 3520 delivers.

More accurate defect detection using PSV™ software

The Sentinel 3520 is controlled by the sigPOD running Sciemetric’s PSV™ (process signature verification) software which measures thousands of datapoints during each test for more accurate pass/fail decisions.

This sigPOD controller also allows you to access visualized control charts, histograms and other SPC tools right at the station. Expand your solution to collect, store and analyze data across stations or the plant with QualityWorX and Sciemetric Studio.

Performing in the most challenging leak test situations on the line

- Testing large parts, up to 1000L

- Testing variable volume parts with multiple cavities

- Compensating for temperature fluctuations affecting test

- Achieving balanced accuracy, cycle time, and Gage R

Leak and Flow Test Instrument: Test Types

Depending on your test needs, the Sentinel 3520 can be configured to meet your requirements for pressure range, flow meter range and flow configuration. The Sentinel 3520 supports the following test types:

- Pressure/Vacuum Decay: Leak Standard

- Pressure/Vacuum Decay: ΔP

- Pressure/Vacuum Decay: ΔP/ΔT

- Occlusion: Pressure or Vacuum

- Ramp to Proof: Pressure (Burst Test)

- Pressure Verify

- Customizable Pressure / Flow Sequencing

- Mass Flow (Flow Models)

- Test Volume Verification (Flow Models)

Highlights

- Pressure measurement and control resolution down to ±0.000,01 psi

- Flow measurement down to ±0.2 % of full scale

- High flow fast fill up to 300 SLPM

- Test parts from 1 cc to 1,000,000 cc in volume

- Helium evacuate and fill

- Customizable pressure and flow sequencing

- sigPOD controller equipped with PSV software, using digital process signatures for advanced test analysis

- Use the sigPOD controller to conduct an additional in-process test such as press-fit, weld or dispense monitoring

—

Hystrong is the Only Authorized Unit of Cincinnati Test Systems (CTS) in Vietnam, with a team of experienced Technicians.

Contact Hystrong Vietnam for advice on installing the most suitable system! Contact now>>>

Facebook: CincinnatiVN

Hotline: (+84) 919-995-040 (call/zalo)

Tiếng Việt

Tiếng Việt

Reviews

There are no reviews yet.